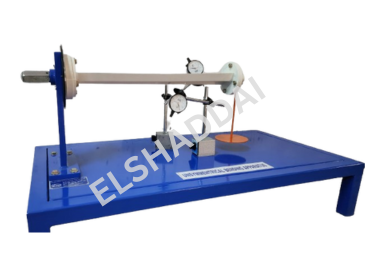

Apparatus consists of sturdy base frame and Channel, Equal angle, Semicircle and Z-Section are supplied with apparatus. Standard length of each of the four sections in M.S. is supplied. Each is provided with end clamp for fixing to the rigid bracket. A special load hanger is provided so as to change the load position so that with the help of two dial gauges the vertical plane of Shear centre for the particular section can be determined.

Determination of the vertical plane of shear centre for different cross sections commonly used for structures

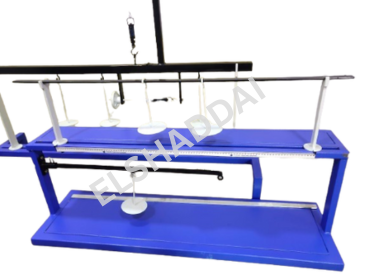

Beam Test Apparatus is a rigid setup where beams can be tested for deflection and bending moment. All types of beams can be tested in this setup. The beam support is movable so that users can use different length beams wherever they want in setup. Digital dial gauge is coming along with the equipment which can measure deflection very accurately. Slotted weight also available for placing known weight over the beam.

Apparatus consist of an angle of size 1” x 1” x 1/8” or in equivalent metric units of length 80cm is tied as a cantilever beam. The beam is fixed at one end such that the rotation of 450 intervals can be given and clamped such that the principal axis of its cross-section may be inclined at any angle with the horizontal and vertical planes. Also arrangement is provided to apply vertical load at the free end of the cantilever and to measure horizontal and vertical deflection of the free end. A dial gauge with magnetic base is supplied with the apparatus.

A Wagner beam made out of aluminum rivets, of

An experimental apparatus to investigate the stresses and strains within a structure in relation to bending loads.

This equipment is a digital type which consists of a load cell to measure the load applied to the column. Both pins and fixed joints of the column can be measured through this apparatus. This equipment is available with different variants. Both manual applying and motorized applying load are also available. This equipment can be customized according to the customer requirement. The accuracy and precision is high and unmatched with any of its kind. In this equipment any shape of the column can be tested such as square, rectangle and circular

Determination of Fringe constant of photoelastic material using:

Determination of stress concentration using photo elasticity for simple component like plate with a hole under tension 2D crane hook

Determination of Fringe constant of photoelastic material using:

Determination of stress concentration using photo elasticity for simple component like plate with a hole under tension 2D crane hook

To determine the central deflection of a simply supported beam loaded by a concentrated load at midpoint and hence determine the modulus of elasticity of the material of the beam

The apparatus provided a comprehensive unit to perform the vibration experiments. A universal frame is provided upon which quick and easy assembly of various experiments can be done. The unit is self-contained to safely store spares. The students can easily assemble the experiments and study the theory of vibrations practically.

Thin-Walled Pressure Vessel is designed to investigate stresses and strains in a thin-walled cylinder under internal pressure. Steel cylinder working to 70 bar. Cylinder fitted with 6 strain gauges wired to a selector switch. Self-contained hydraulic pump and flow control valve and bourdon tube pressure gauge.

The MODULAR 2S is a single pump / single resin trap mobile vacuum system for manufacturing composites using processes such as resin infusion and vacuum bagging.

In a bifilar suspension, the pendulum body is suspended over two threads. The pendulum body oscillates in a plane purely transnationally without rotation. This kind of pendulum can be considered as a mathematical pendulum. In a trifler suspension with three threads, the pendulum body is set in a torsional vibration. The torsional vibration can be used to determine the moment of inertia by experiment. A beam, a cylinder or a circular ring are used as pendulum bodies. The length of the threads can be adjusted using clamping devices. The moments of inertia of the pendulum body can be calculated from the measured oscillation period. The oscillation period can be varied by changing the thread length.

© elshaddaiengineeringequipments 2024. All Rights Reserved.